Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

»» WHAT CUSTOMIZED WE SUPPORT ««

Various Shapes

High Quality Coating

| Coating | Appearance | Technology | Thickness | Salt Sparay Testing(h) |

PCT Testing(h) | Feature |

| Zinc(Zn) |  |

Barrel Plating | 5-10um | 24 | 24 | 1.Zinc plating is a standalone plating with only one layer. It is a self- sacrificing coating, meaning when the material corrodes the outside turns white creating a durable layer of protection. 2.Good protection against corrosion |

| Rack Plating | 5-10um | 24 | 24 | |||

| Nickel(Ni) |  |

Barrel Plating | 10-20um | 48 | 48 | 1. Nickel plating can be multi-layer combination of nickel,copper,nickel or only nickel. The most common plating for magnets. 2. Industrial standard. Good work stability. Sufficient protection against corrosion in dry environment, possible allergic reaction on sensible persons. |

| Rack Plating | 10-20um | 24 | 24 | |||

| Epoxy(Ep) |  |

Rack Plating | 10-20um | 96 | 24 |

1. Epoxy plating can be multilayered in Nickel, Copper,Epoxy or only Epoxy. Great for outdoor applications. |

| Gold(Au) |  |

Barrel Plating | 10-20um | 48 | 24 |

1. Well known for its corrosion resistance.Layered in Nickel Copper & Gold on top. |

| Rack Plating | 10-20um | 24 | 24 |

Magnetizing Direction

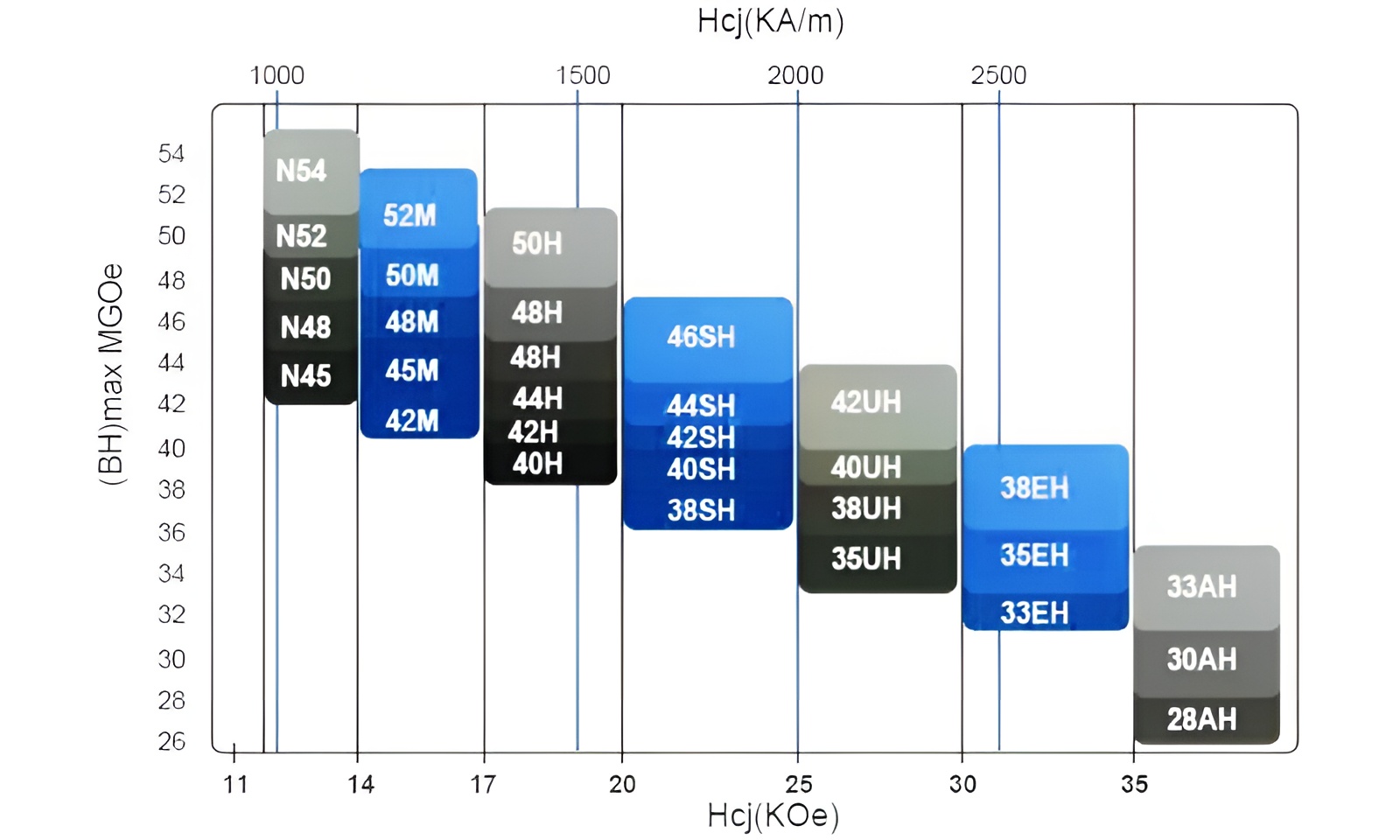

High Performance

There are special grades of materials that can withstand different ranges of temperatures, so letters are added at the end to distinguish them. Such as N45SH, N42M, N35EH, etc., these letters represent the temperature rating and maximum operating temperature that the magnet can withstand before it begins to permanently lose its magnetism.

ONE-STEP OEM SERVICES OF BULK ORDERS

3 hassle-free steps in constructing your bespoken magnet

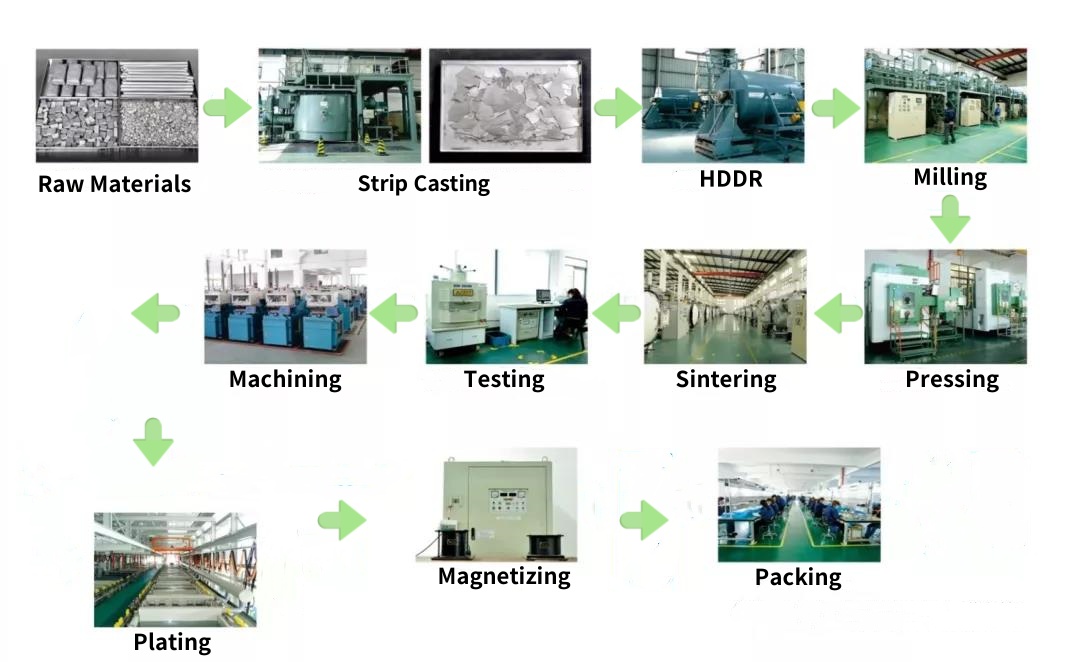

»» PROFESSIONAL PRODUCTION FLOW ««

Want to know more details about customized? GET IN TOUCH

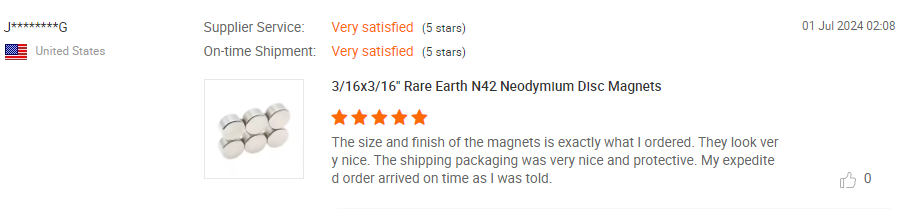

»» GOOD FEEDBACK FROM CUSTOMERS ««

|

|

|

|

|

|

|

|

|

|

»» FREQUENTLY ASKED QUESTIONS ««

Q: Can I have the sample?

A: Yes, we can provide free samples.

Q: What is the MOQ?

A: Usually 100 pcs, according to your size of magnets.

Q: Can print my logo on magnet product or package?

A: Yes, please inform us formally before our production and send your drawing to us.

Q: How to ensure consistency in product quality across different batches?

A: To ensure consistency, we use standardized production processes and conduct batch-to-batch comparisons.

Q: What is the tolerance? How to control the tolerance?

A: +/-0.05mm. First, before grinding and cutting, we inspection the magnet tolerance. Second, before and after coating, we will inspection the tolerance by AQL standard. Finally, before delivery, will inspection the tolerance by AQL standard.

Q: What is the lead time for customized orders?

A: Our lead time is 5-15 days, depending on the complexity of the design and volume of the order.

Q: What's your terms of payment?

A: T/T, Ali pay, PayPal and Western Union, etc.

Q: Which courier company do you work with? How long usually take to make delivery?

A: We are working with DHL, FedEx and UPS, the delivery time is 3-7 days.