Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

NdFeB magnets are super strong magnetic materials with powerful chemical activity. There are tiny pores and cavities inside, and it is easily corroded and oxidized in the air. After the material is corroded or the components are damaged, the magnetic properties will be attenuated or even lost over time, thus affecting the performance and life of the entire machine. Therefore, strict anti-corrosion treatment must be carried out before use. At present, the anti-corrosion treatment of NdFeB generally adopts electroplating, chemical plating, electrophoresis, phosphating and other methods. Among them, electroplating, as a mature metal surface treatment method, is the most widely used.

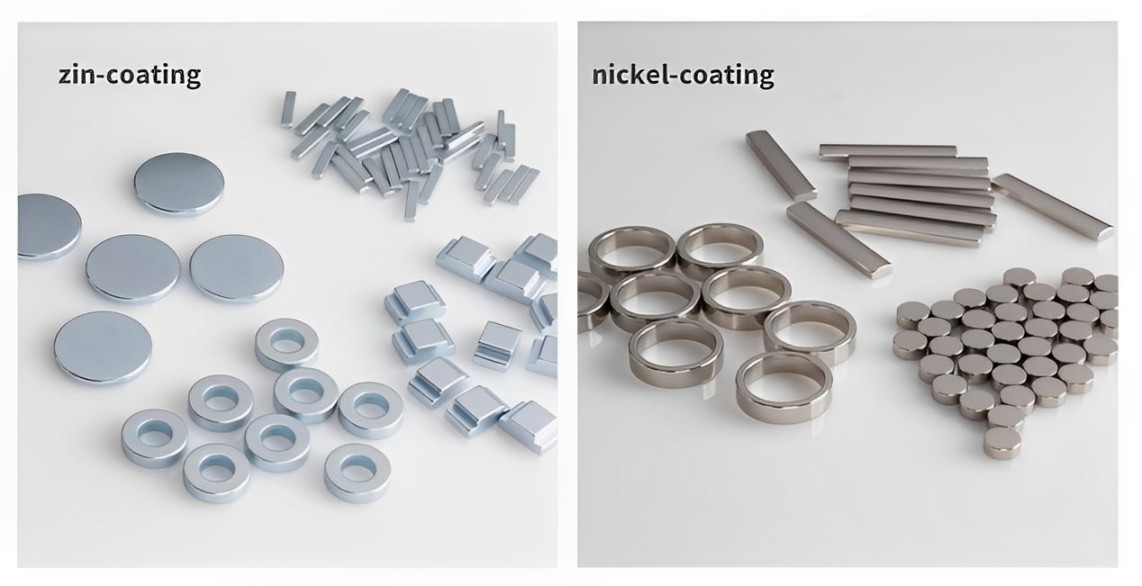

The most commonly used coatings for NdFeB powerful magnets are zinc plating and nickel plating. They have obvious differences in appearance, corrosion resistance, service life, price, etc.:

1. Differences in polishability: Nickel coating neodymium magnets are superior to zinc-plated magnets in terms of polishing, and their appearance is brighter. Those with high requirements on product appearance generally choose nickel plating, while some magnets are not exposed, and those with relatively low requirements on product appearance are generally galvanized.

2. Differences in corrosion resistance: Zinc is an active metal and can react with acid, so its corrosion resistance is poor; after nickel plating surface treatment, its corrosion resistance is higher.

3. Differences in service life: Due to different corrosion resistance, the service life of zinc plating is lower than that of nickel plating. The main reason is that the surface coating easily falls off after a long time of use, causing the magnet to oxidize, thus affecting the magnetic performance.

4. Price differences: Galvanizing is extremely advantageous in this regard. The prices from low to high are galvanizing, nickel plating, epoxy resin, etc.

When choosing NdFeB magnets, you need to consider which coating to use based on factors such as operating temperature, environmental impact, corrosion resistance, product appearance, coating bonding strength, and adhesive effect. If you want to know more about magnets, please feel free to consult our professional neodymium magnet suppliers and we will patiently answer your questions.

Hi! Click one of our members below to chat on