Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

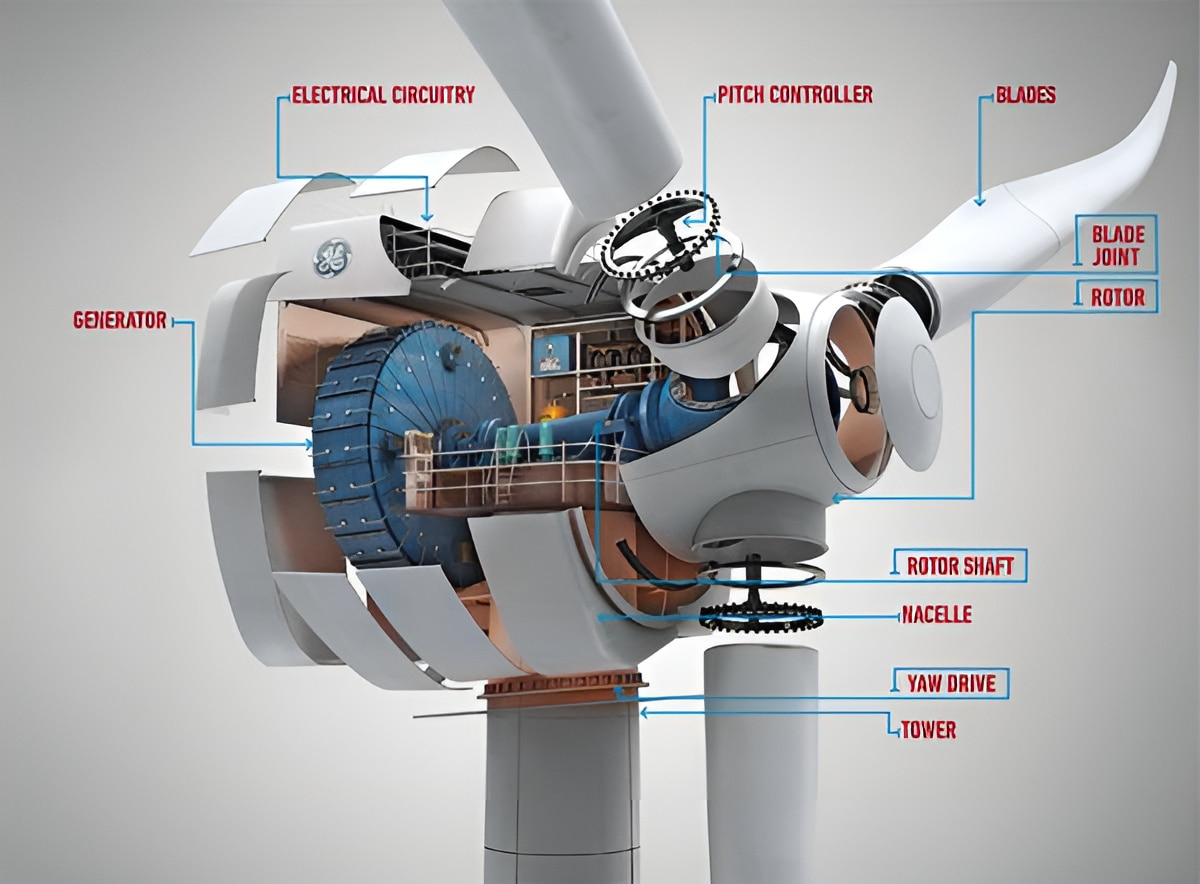

The fact that wind turbines are generally accepted as a primary source of power and produce entirely clean energy (without emitting anything toxic to the environment) has made them a staple in the power industry. Central to this is the presence of permanent magnets, such as rare earth permanent magnets. The use of rare earth magnets in wet generators has many advantages, including high magnetic energy density, stable magnetic properties, smaller size and weight, high temperature stability, etc., which makes rare earth magnets commonly used magnets in wet loads. materials that can improve the efficiency and performance of generators.

Neodymium magnet's working principle:

The main function of neodymium magnets used in wind turbines is to generate magnetic fields and drive the generator to generate electricity. The rotor of a wind turbine consists of permanent magnets with multiple magnetic poles, which are usually made of neodymium iron boron magnets. When wind blows over the rotor blades of a wind turbine, the rotor blades rotate, causing the magnet rotor to rotate. The magnetic field produced by the magnets on the rotor interacts with the coils on the stator, causing an electric current to be generated in the coils. This current is transmitted through the circuit and eventually converted into usable electrical energy

Advantages of neodymium magnet:

1. Temperature stability of custom NdFeB permanent magnets

Wind turbines can work in the wilderness and withstand heat and cold. At the same time, motor losses also cause the motor temperature to rise. Sintered NdFeB magnets can operate at 120°C.The Curie temperature of NdFeB permanent magnet alloy is approximately 310°C. When the temperature of a magnet exceeds its Curie point, it changes from ferromagnetic to paramagnetic. At the Curie temperature, the remanence of NdFeB decreases as the temperature increases, and its remanence temperature coefficient (Br) is -0.095-0.105%/. The coercive force of Nd-Fe-B decreases with increasing temperature, and the coercive force temperature coefficient β (jHc) is -0.54-0.64%. If the appropriate coercivity is selected, the magnet will still have a sufficiently high coercivity at the maximum operating temperature for which the motor is designed; otherwise it will lose excitation.

2. Magnetic performance consistency of wind powered NdFeB magnets

Large permanent magnet wind turbines typically use thousands of neodymium magnets. Each pole of the rotor contains many magnets. The consistency of the rotor poles requires the consistency of the magnets, including dimensional tolerances and magnetic properties. The so-called magnetic performance consistency includes: the magnetic performance deviation between different individuals should be small, and the magnetic performance of a single magnet should be uniform.

3. Corrosion resistance of NdFeB magnets

NdFeB alloy contains reactive rare earth elements, which are prone to oxidation and rust. In applications, NdFeB magnets should be considered a surface corrosion protectant unless it is encapsulated and isolated from air and water. Common anti-corrosion coatings are nickel plating, zinc plating and electrophoretic epoxy resin. Surface phosphating treatment can prevent NdFeB from rusting in a relatively dry environment for a short period of time.Rare earth intermetallic compounds can react with hydrogen at certain pressures and temperatures. When NdFeB magnets absorb hydrogen, it heats up and decomposes. Hydrogen fragmentation during NdFeB production takes advantage of this property.