Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

For different working environments, the coating of neodymium magnets needs to be changed. If you are using a neodymium magnet in a humid environment, it is a good idea to give it a rubber coating, otherwise it may become corroded, which will destroy the magnetic field. Therefore, it is very necessary for magnets to be coated.

There are many types of strong NdFeB coatings, some of the mainstream coatings are nickel-copper-nickel, zinc, epoxy, gold, rubber, etc. Each type of coating has its own unique characteristics. Next, we will introduce the relevant knowledge and benefits of rubber-coated neodymium magnets in detail, hoping to help you make a choice.

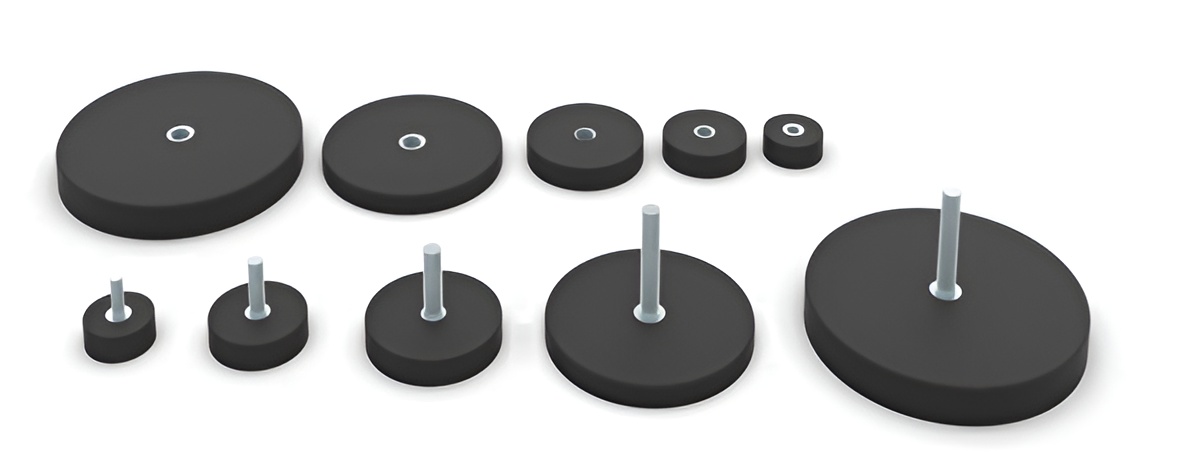

First of all, for rubber-coated magnets, it is common to use black isoprene rubber as a coating to wrap the magnets. They are one of the most widely used magnets in various industries. Rubber coated magnets are known to be very durable and provide excellent friction and protection.

Secondly, rubber coated magnets are available in different designs such as external threads, internal threads, countersunk holes, and tapped holes. Due to its high slip resistance, this type of magnet is commonly used in fixing and mounting applications.

Finally, the advantages of rubber coatings are numerous.

1. Strong corrosion resistance: This is the point that people pay most attention to and take advantage of. Neodymium magnets are generally prone to oxidation and corrosion, but rubber materials are resistant to corrosion.Usually the rubber coating is much thicker than other types of coatings, which also allows the neodymium magnet with this coating to block the contact of air and moisture in a humid environment, thereby reducing the oxidation and corrosion rate of the magnet surface and prolonging the the service life of neodymium magnets.

2. Convenient installation and application: The rubber coating can provide smoothness and softness to the surface of the neodymium magnet, making it easier to install and use with other parts. This is very useful for some special shapes neodymium magnets and application requirements.

3.Shock absorption and anti-slip function: Rubber has certain buffering and shock absorption properties. The rubber coating can reduce the collision and vibration of neodymium magnets with other surfaces and play a protective role.In addition, the rubber coating can also increase the friction of the surface and provide anti-slip function, making the neodymium magnet more stable during use. Ordinary coatings tend to slip sideways when adsorbed on smooth surfaces, but rubber coatings do not.

4. Reduce magnetic loss: The rubber coating has certain insulation properties, which can reduce the magnetic field leakage of neodymium magnets and reduce magnetic loss. This is beneficial for applications where the magnetic force needs to be kept as high as possible.

There are also some advantages, such as good temperature characteristics. The rubber-coated magnet can work normally at a high temperature of 80 degrees Celsius and a low temperature of minus 40 degrees Celsius. There are many kinds of colors, the most common ones are black, but they can also be adjusted to red , blue, yellow, green, and other colors according to needs.

In short, rubber coating is suitable for use in harsh environments, but generally irregular sizes may require mold opening. In this case, it is best to communicate with the neodymium magnet factory in advance.