Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

3D printing is closely related to custom neodymium magnets.

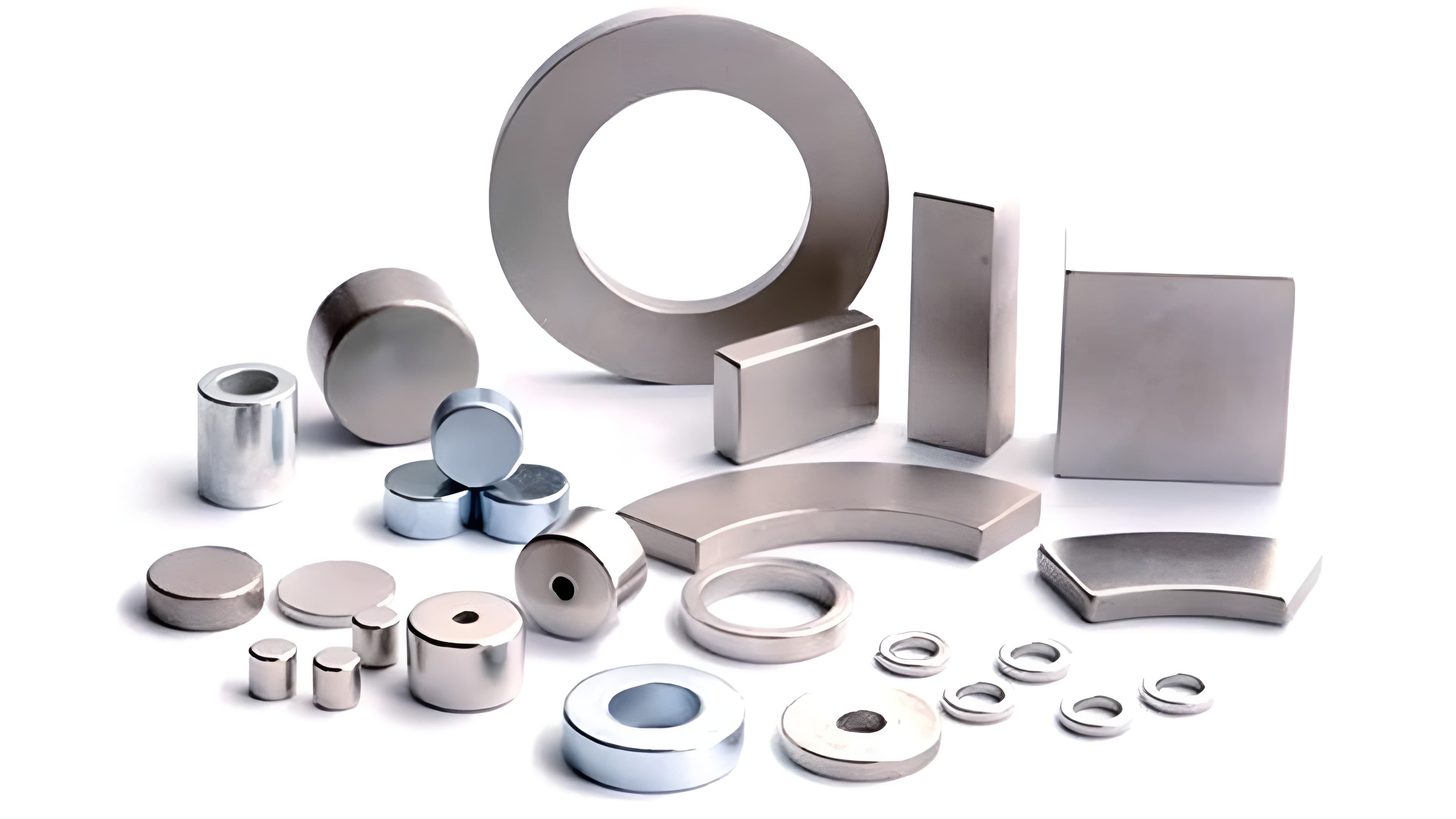

Neodymium magnets are a powerful permanent magnet material widely used in various fields such as motors, sensors, medical equipment, etc. 3D printing is a manufacturing technology that accumulates materials layer by layer. It can directly manufacture objects based on design models without traditional cutting and processing processes.

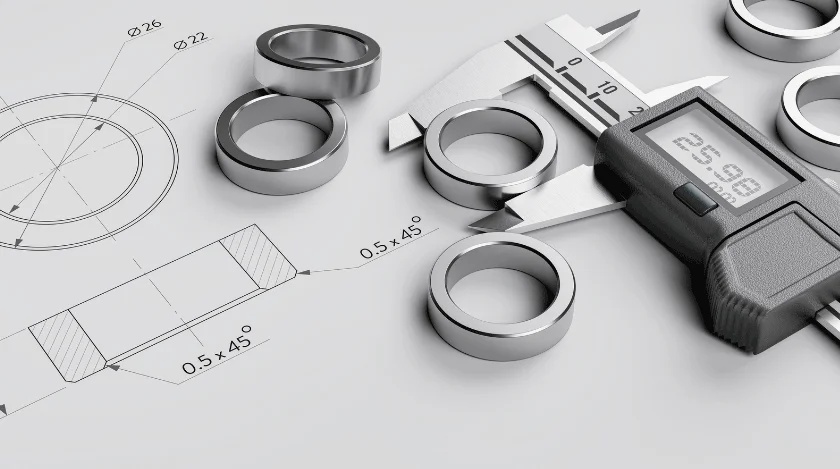

Traditional methods for manufacturing neodymium magnets include pressing, casting, and cutting processes, but these methods usually require customized molds and special equipment, which are costly and require a long cycle.

For some complex shapes of custom neodymium magnets, such as arc neodymium magnets, hoof neodymium magnets, trapezoidal neodymium magnets, etc, traditional manufacturing methods may be difficult or expensive. Using 3D printing technology, neodymium magnets of various shapes and structures can be flexibly printed, including magnets with complex internal structures and customized requirements. This is very valuable for some special applications and personalized needs.

Using 3D printing technology to manufacture neodymium magnets also has the following advantages:

1. Rapid manufacturing: 3D printing technology can achieve rapid prototyping and low-volume production, and can quickly manufacture neodymium magnet samples or small batch products as needed.

2. Free design: 3D printing technology can flexibly achieve a high degree of freedom in design, and neodymium magnets can be designed and improved according to specific needs to meet specific application needs.

3. Customized production: Through 3D printing technology, neodymium magnets can be produced according to customers' individual needs, with a higher degree of customization.

4. Complex structure manufacturing: 3D printing technology can realize the manufacturing of complex internal structures, and can achieve complex shapes and structures in neodymium magnets to improve magnetic performance or achieve specific application requirements.

5. Save materials: 3D printing technology can use materials on demand, reduce material waste and improve resource utilization.

All in all, manufacturing neodymium magnets through 3D printing technology can provide a more flexible, fast and customized production method to meet the needs of various applications, and bring certain innovations to traditional neodymium magnet manufacturing methods.